MAXIMIZE MANUFACTURING

With an unbreakable supply chain and virtually unlimited manufacturing capacity, Arvind Engineers is your solution for getting the components you need when you need them.

ARVIND ENGINEERS

Arvind Group established in 1986 has built a steadfast image in manufacturing Automobile Sheet Metal Components, Welded Sub-Assemblies such as Lower Control Arms, Engine Mountings, Steering Brackets etc. for Passenger Cars, Back Plates for Commercial Vehicle, Composite Break Block Back Plates for Railways.

Hot Forgings for Automotive industry.

Sheet Metal Fabrication for Tractor industry and Elevator industry.

Message from the management

Industries We Serve

Passenger

Cars

Commercial Vehicles

Railway Locomotives

Fabrication & Elevators

Metal Casings & Steel Pallets

OUR SERVICES

Stamping

Power Presses

Hydraulic – 3 upto 500 Ton Capacity Presses

Pneumatic & Mech.

(102 Nos up to 500 T)

Tool Room – In-house

For manufacturing

Tools Dies & Fixtures

Welding

Welding Machines

Manual Co2 Mig – 75

Automatic (SPMs) – 12

Spot Welding – 3

Projection Welding – 3

Robotic Welding – 4

(ABB & OTC

DAIHEN MAKE

MANIPULATORS)

Machining

CNC-Machines

Vertical Milling – 2

CNC-Turning – 2

Milling Machine – 4

Drill Machine – 15

Lathe – 2

Orbital Rivet M/c – 1

Hot Forging

Machine Details

Friction Drop Hammers – 6

Forging Screw Press – 1 ( 100 Ton)

Mech Forging Press – 1 ( 1350 Ton)

Induction Billet Heaters – 8

Electric Heat Treatment Furnace – 3

Continuous Electric Automatic Normalising Furance. – 1

Tool Room Equipped with VMC & Conventional Machines.

Standard Room

Special Fabrication

Machine Details

CNC Turret Punch – 2

CNC Hydraulic Press – 1

NC Press Brake – 2

Power Press upto 75T – 4

Shearing upto 4mm thk -1

LASER CUTTING M/c

Make : AMADA LCJ3015 AJ

Tool Room – In house

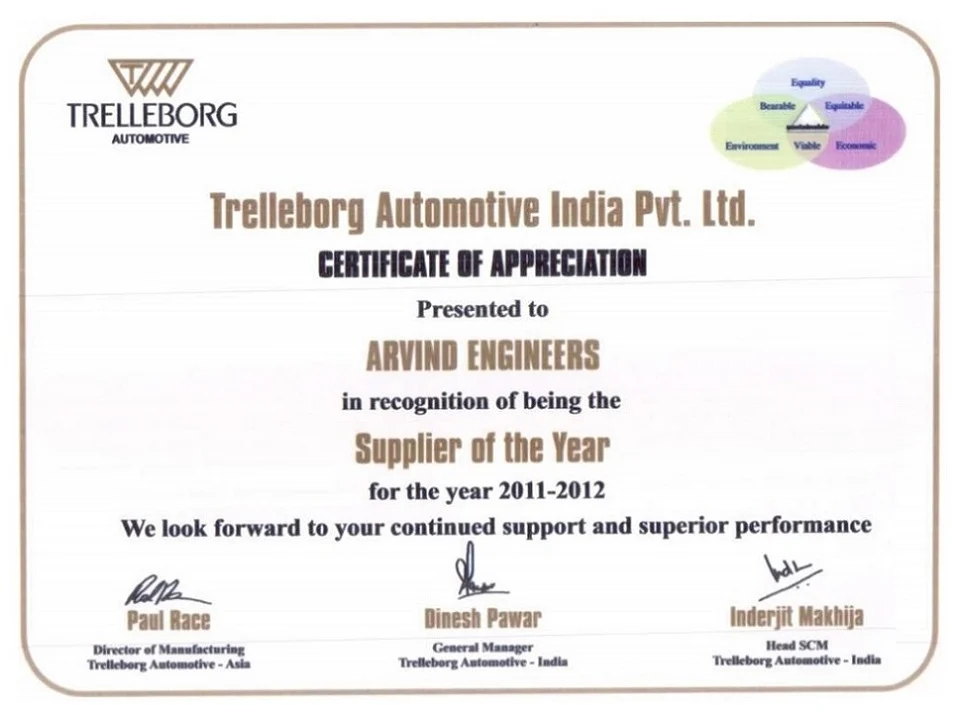

Awards & Certifications