Who We Are?

About us

Arvind Group established in 1986 has built a steadfast image in manufacturing Automobile Sheet Metal Components, Welded Sub-Assemblies such as Lower Control Arms, Engine Mountings, Steering Brackets etc. for Passenger Cars, Back Plates for Commercial Vehicle, Composite Break Block Back Plates for Railways.

Hot Forgings for Automotive industry.

Sheet Metal Fabrication for Tractor industry and Elevator industry.

SHEET METAL & FABRICATION

HOT FORGING

Our Mission

- Best Quality - Zero Defect Products

- First Time Right

- A Skilled & Motivated Workforce

- Engineered Innovation

- Ensure Customer Satisfaction

- Pursue Excellence Through Quality Management

- Environmentally Responsible

Our Journey

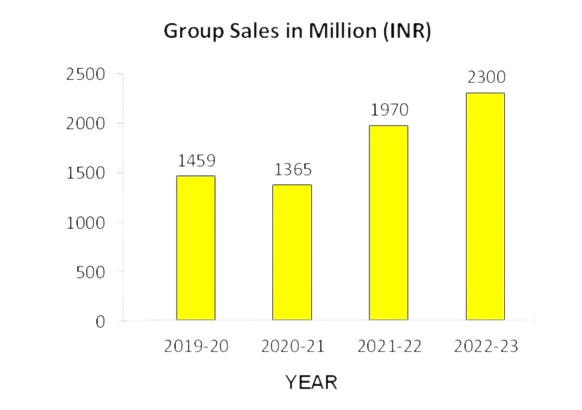

Our Growth

Our Expansion Plans

NEW MFG. UNIT AT EPIP – NEEMRANA

ARVIND AUTOTECH PVT LTD.

For manufacturing of Steel Pallets & Casings (An Envoirment friendly Packaging Solution Manufacturing Unit for All Industries)

NEW MFG. LOCATION AT PRITHLA (HR.)

ARVINDO HITECH PVT. LTD.

Started Manufacturing Sheet Metal Components & Elevator Fabrication for M/s Schindler India Ltd

UPGRADING PRESS LINE & ADDING ROBOTIC WELDING LINE

ARVIND INTERNATIONAL

Work in progress on upgrading Pressline with latest technology mechanical/ Pneumatic & Hydraulic machines upto 600 ton capacity & adding robotic weldin line with latest tech robots.